What is Vinyl Banner | Vinyl Banner | Flex Banner

Unthika RoekwibunsiWe accept vinyl banner production, vinyl, vinyl printing, vinyl banner, economical advertising signs, can be used for both indoor and outdoor work. Vinyl signs are highly durable, cheap compared to the size of the sign. Vinyl has low cost, can be printed from small to large sizes attached to buildings.

*Vinyl signs* can be used for advertising, clearly standing out and being seen from afar. Vinyl can be printed from small to very large sizes (at the same size as vinyl billboards found on expressways). Small shop owners with storefronts, from SME to public companies, can choose to print vinyl signs for advertising. Whether opening a shop, running a promotion, holding a meeting or seminar, setting up a booth, or exhibiting at an Expo, you can use vinyl signs as banners for advertising.

What is vinyl? What is vinyl made of?

Vinyl is a special type of plastic that is a mixture of high-quality plastic and various additives, such as sunlight-resistant agents . The surface we see is usually PVC with polyester fibers woven in the middle, shock-resistant agents, weather-resistant agents, and heat-resistant agents. In addition to being resistant to UV rays and changing weather conditions, vinyl is also a material that is free from termites or insects, erosion or warping, rust, rainwater leakage, is not flammable, and also reduces energy consumption. Therefore, it is popularly used to produce outdoor equipment.

Advantages of vinyl printing

- Vinyl Banner is cheap, save budget, low production cost, can produce large quantities quickly.

- Vinyl signs can be made from small to very large vinyl for attaching to buildings. They are eye-catching, highly visible, and can be installed anywhere.

- Vinyl advertising signs are waterproof and can be used both inside and outside the building. They are resistant to sunlight and UV rays.

- Vinyl is a non-flammable material that increases safety.

- Vinyl banners are easy to clean dirt and dust.

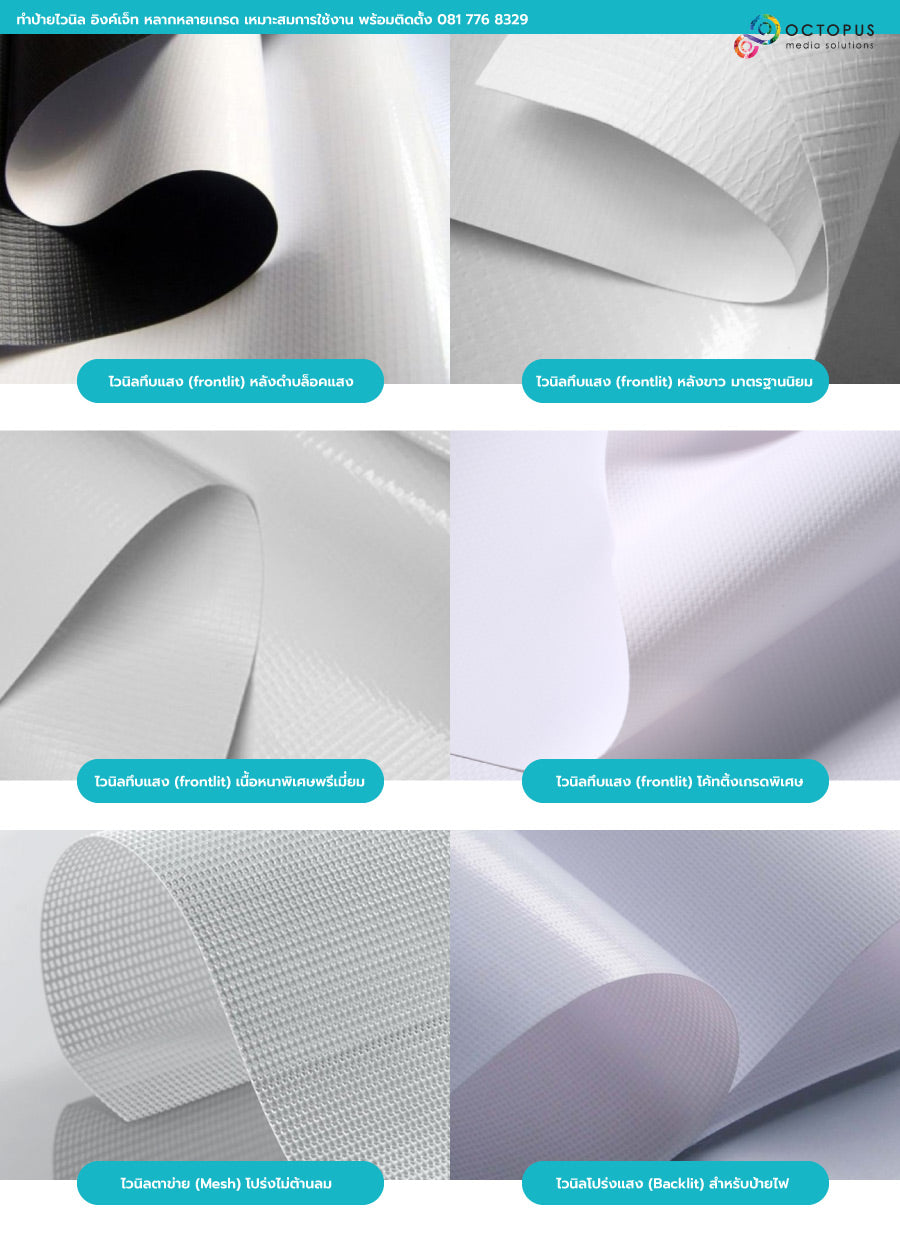

Vinyl signs are divided into two main types: opaque vinyl and translucent vinyl.

Opaque vinyl is vinyl that has a chemical coating on the back. When inkjet printed and exposed to light, it cannot be seen through. It is divided according to its use as follows:

- Vinyl signs with white backing, suitable for general inkjet printing.

- Vinyl signs with a grey/black back are suitable for hanging signs with two sides. They help reduce image overlap when sunlight shines through.

- Double-sided printable vinyl banners This type of vinyl is suitable for UV flatbed printers, which are sheet-type printers that can print on both sides accurately.

Backlit vinyl is vinyl that has a thinner chemical coating on the back than opaque vinyl, allowing light to pass through. There are two types:

- Transparent vinyl signs are vinyl that allows light to pass through, so they are commonly used for making light boxes that we see on signs outside shops. We can inkjet using Profile Backlit. Since we have to shine a light from behind, we have to use printing that uses a higher density of ink so that when the light is shined on, the color doesn't change. Transparent vinyl can be used for inkjet printing directly or it can be used as a technique to stick a transparent sticker over it as well, depending on the type of work required.

- Vinyl signs, mesh type , is a vinyl that can reduce wind impact better than general transparent types. It can be used to stretch along tall buildings or light boxes on tall buildings. The distance between the nets will vary and can be selected according to suitability.

Vinyl specifications you should know and how to choose them for printing signs

- Weight is the weight per square meter of vinyl, expressed in grams. For example, 360g/m2 means the vinyl weighs 360 grams per square meter.

- Width is the width of the vinyl. It starts from 0.92, 1.22, 1.32, 1.52, 1.82, 2.22, 2.52, 2.82, 3.20, 5 m. If the workpiece is wider than this, it must be connected with meticulous care. There are both hot glue, cold glue, hot air seam vinyl, or high-frequency seam machines, etc.

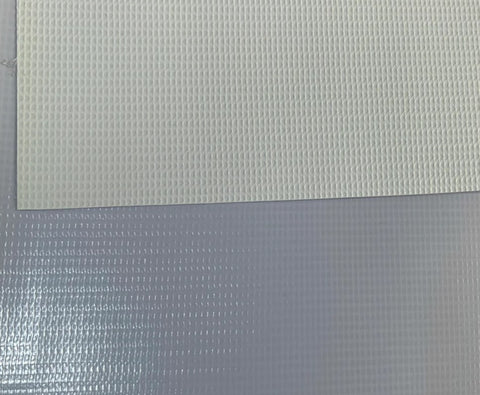

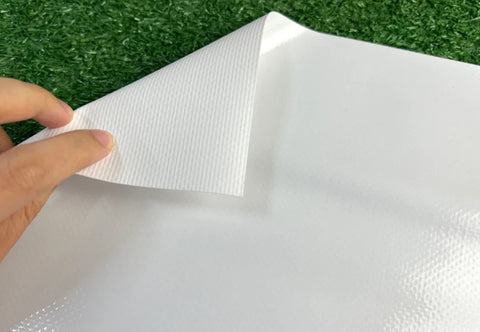

- Base Material is the plastic seeds used to make vinyl. It is mostly made of Polyester, laminated on both sides. In the middle is a fiber that holds the plastic seeds together to create the strength of the material.

- Surface is the type of vinyl surface. Most commonly, Glossy is the most popular. Matte is less popular.

Selecting materials for small vinyl signs (not exceeding 3×3 m.) can use vinyl with a thickness of 360 - 510g by punching eyelets or threading pipes for installation on site.

Selecting materials for large vinyl signs (from 3 m. and up) should use vinyl with a thickness of at least 440g to ensure that the welding work is durable and strong, with enough weight to withstand wind and other weather conditions, or it may be necessary to drill a Wind Slit to reduce wind resistance.

The frequency and thickness of the fibers in the vinyl sheet are another part that must be selected appropriately. Even if the thickness is high, the weight in grams per square meter is high, it does not always mean that it is strong. The frequency and thickness of the fibers are another very important part that indicates the quality of the vinyl sign. Good quality vinyl signs, durable vinyl signs, long service life, not brittle and easily broken, can be checked from here as well. Especially if the sign is large, the lines must be thick and very dense.

In addition to large vinyl banners, you can also make vinyl banners with stands. The most commonly seen ones are *Japanese flags*. Japanese flags or J-flags are suitable for setting up booths, organizing events, as signs in front of clicks, signs in front of restaurants. They require little installation space and are easy to remove. One person can use them.

We are happy to provide advice on vinyl signs and other advertising media . Contact Octopus Media Solutions. You can trust us because we are your "marketing team". 081-776-8329 or LINE ID: @OctopusDesign

Cr. Printastic.com